Using MRI to Determine the Velocity Depth Profile of Granular Materials in the Horizontal Rotating Cylinder

|

|

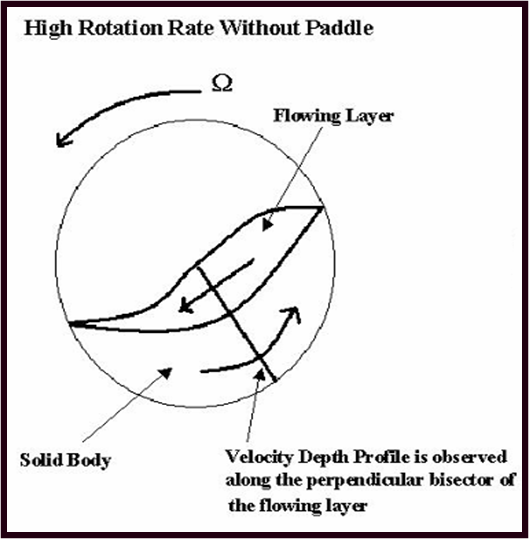

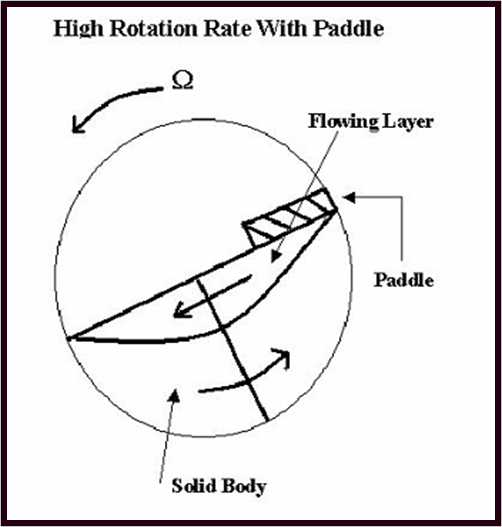

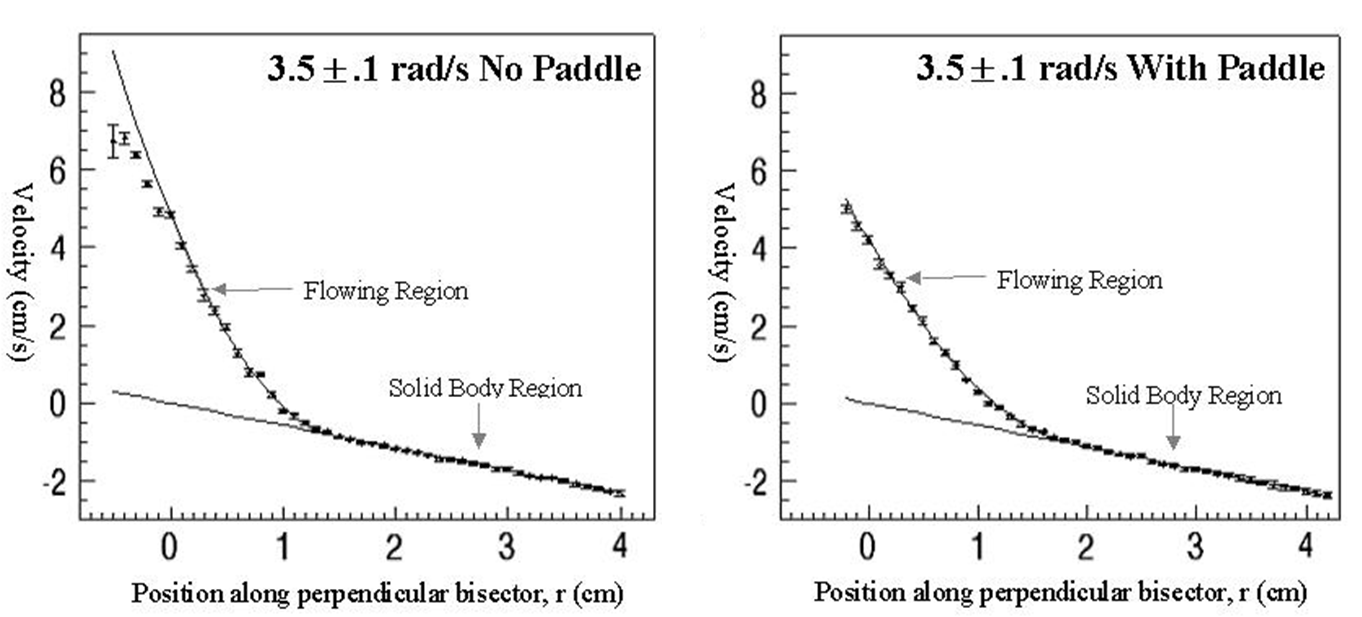

Can we recover the quadratic fit by adding a paddle to prevent particles from leaving the surace as they emerge from the soild body layer? |

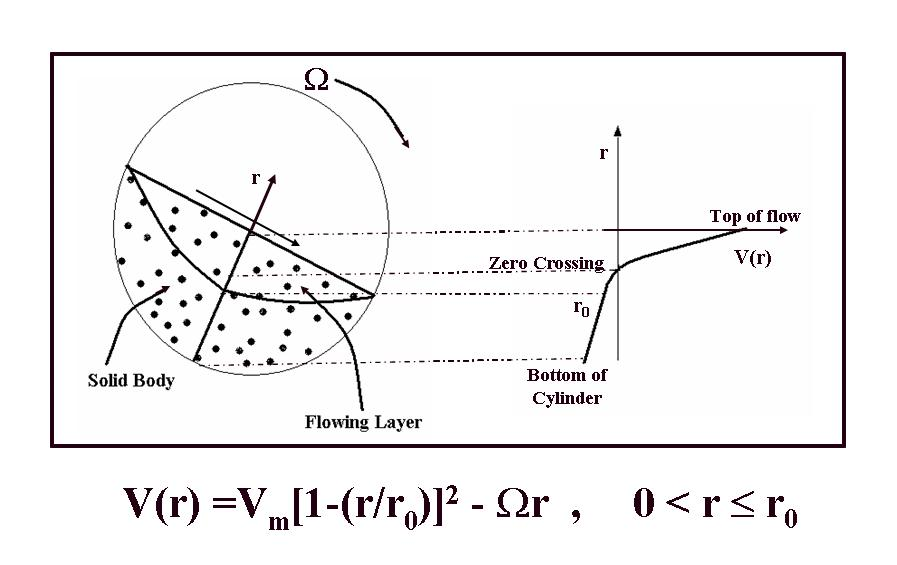

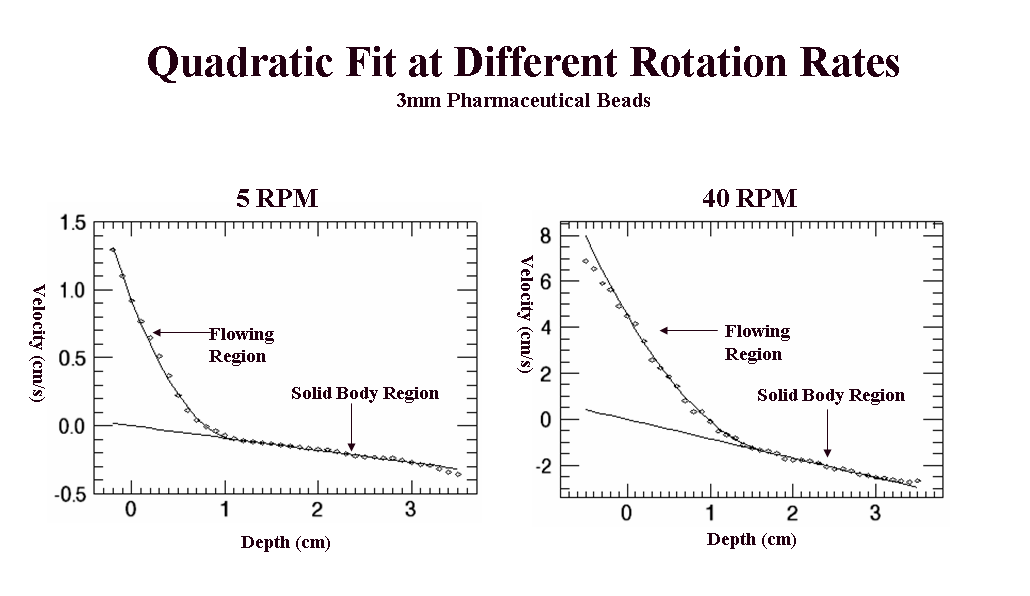

The quadratic function observed offers an attractive alternative to a hybrid of two straight lines joined by a transition region. The hybrid works well for flows at moderately fast rotation rates (without a paddle) because in such cases the particles near the free surface slow down compared to the quadratic, accidentally making the velocity dependence appear linear. However, as the rotation rate is increased more the velocity profile continues to deviate further from the quadratic function, eventually bending over as the highest particles begin to flow slower than those beneath. This result strongly suggests that a quadratic velocity depth profile may be a fundamental property of granular shear flows in horizontal rotating cylinders when the effect of the cylinder rotation is to transport the particles from the end of the flow to the beginning without imparting velocity perpendicular to the free surface flow of the particles upon reaching the flowing layer. |

REFERENCES:

Sanfratello, L., Caprihan, A., Fukushima, E. Velocity depth profile of granular matter in a horizontal rotating drum (2007) Granular Matter, 9 (1-2), pp. 1-6.

M. Nakagawa, S. A. Altobelli, A. Caprihan, and E. Fukushima, "NMR measurement and approximate derivation of the velocity depth-profile of granular flow in a rotating, partially filled, horizontal cylinder," in Powders and Grains 97, Proceedings of the Third International Conference on Powders & Grains, edited by R. P. Behringer and J. T. Jenkins (A. A. Balkema, Rotterdam, 1997); pp. 447-450.